Rapid prototypes play a critical role in the product development process. Usually, rapid prototypes are used for sales demonstrations, master models, functional analysis, and testing. Nowadays, various Prototype companies use different rapid prototyping technologies. They are mainly classified into subtractive and additive. The following are some of the methods used.

Stereolithography (SLA)

This method has been around for about four decades. Ideally, it is an old 3D printing technique used for commercial purposes. Like other printing technologies, it uses a 3D map file of product design and divides it into different 2D layers. The layers are then solidified with the use of UV light.

The good thing about SLA prototypes is that they are printed with the exact shape as the design. Also, the prototypes are oriented vertically. As a result, there is minimal wastage of materials, and it produces the best surface finish. Therefore, this prototyping technique is perfect for making prototypes for vacuum casting.

Polyurethane Vacuum Casting

This is a great prototyping technique for making mass volumes of pieces. The casting process uses master patterns that can be developed through 3D printing or machining processes. During the process, the pattern forms a silicone mold. The pieces provide great fidelity to the original masterpiece. Another advantage of this method is that it is an economical solution.

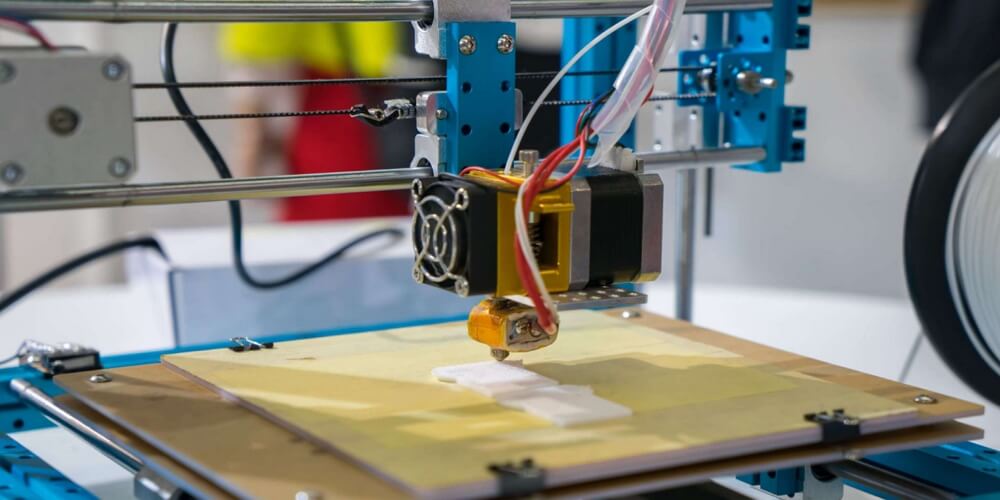

Fused Deposition Modeling (FDM)

This method is popular among hobbyists, small businesses, and inventors. However, it is now widely used in making rapid prototypes. The technique utilizes plastic filament fed through the heated nozzle that melts the resin and creates a bead for making the final shape.

Remember that FDM printing is quite inexpensive. Also, it can be used to accommodate various types of colors and types of plastic. In fact, it is safe for use in the classroom. However, the FDM printed products have poor finish quality and resolution than other industrial methods. The method is recommended for developing rapid prototypes that are modified with minimal investment.

Selective Laser Sintering (SLS)

This prototyping technique uses pressure and heat to mold products from plastic powder or molten metal. In this case, the metal is heated with a laser device and maintained below the melting or liquefaction point. The truth is that SLS parts are made of complex designs as compared to those of SLA. However, the surface texture is a bit rough and may require treatment or finishing. This is a great method for making functional prototypes.

CNC Machining

The truth is that CNC machining is widely used in making rapid prototypes. That is because the technique is quite versatile and can work with any raw material. Also, you can make prototypes quickly and achieve tight tolerances. Since it does not have volume limitations, you can make only the parts required. Therefore, CNC machining is effective for making prototypes that are fully functional and with excellent strength.

Binder Jetting

This is a new prototyping technique that allows for mass production of parts. The good thing about this technique is that several parts can be made at a time. However, the prototypes made are not quite strong as compared to welded ones.