CNC machining is a subtractive manufacturing technique. It is made up of a wide range of machining services, including CNC milling. CNC milling is the process of using cutting tools to take off parts or chips of material from a workpiece. Read here to learn more about CNC milling. If you are looking to understand the various CNC machining services, it will help to understand how the CNC machining process works.

The process of CNC machining

At first look, CNC machining seems like a complicated process. However, this is not entirely the case. You can break down the process into the following phases;

1. Designing

This is the part where the part is designed. Conventionally, parts are designed by creating sketches. However, CNC machining is a modern manufacturing technique, and therefore, this process highly depends on computer technology. In CNC machining, the part is designed using Computer-Aided Design software. When creating the design, engineers have to consider all the elements of the final product carefully. This includes the shape, color, operating conditions, and dimensions. The quality of the CAD will influence the outcome of the production process.

2. Conversion

Once the CAD model is created, it has to be converted into a CNC program which has to be functional. The conversion process is done using Computer-Aided Manufacturing software. The CAM software extracts the geometrical requirements from the original CAD model. It then translates the requirements into a compatible programming language. The preferable programmable languages are G-code and M-code. This is a language that the machine can understand. The G-code or M-code will be used to issue instructions for the machine’s mechanical operations.

3. Machine preparation

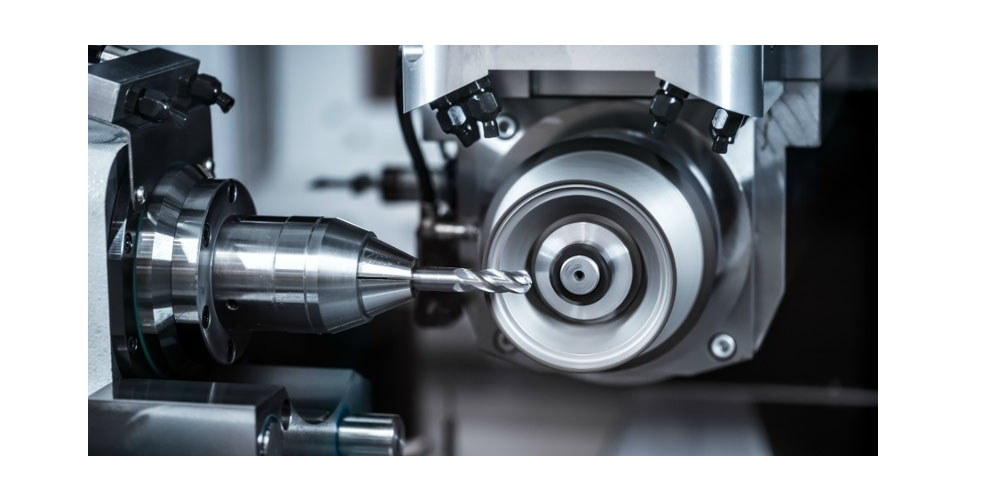

The next phase of the process is the preparation of the machine. Here, the operator has to set up the machine and the raw material. The material is chosen depending on the type of product being manufactures. It is also chosen based on the CNC manufacturing technique applied. For instance, in CNC milling, metal is used. The operator also has to ensure that the right cutting and drilling tools are used. The tools must be properly installed and matched with the right end mills. This part of the phase is also where the workpiece is set up. Normally, the workpiece is set up on a stationary clump or attached directly to the machine.

4. Execution

The final step is the execution of the CNC manufacturing process. Here, the operator plays the role of executor. However, this is where his work ends. Once the process has been executed, the machine takes over the rest of the operation. The CNC program controls the movement of the tools until the desired product shape and dimensions are achieved.

Conclusion

CNC machining devices come in a wide range of styles. They are categorized depending on the method used to remove material from a workpiece. CNC mills, turning machines (or lathes), CND drilling machines, and multi-axis CND machines are the most common types of CNC machining devices. The most challenging part of CNC machining is the first phase (CAD creation). Therefore, the process requires professional assistance. However, the final three parts are very easy. With a little training, anyone can complete them.